Uni-Mill conical screen mill

The Uni-Mill cone mill is based on Hanningfield’s experience in particle reduction for the process industry.

Grinding with a Cone Mill is the ideal way to achieve a fine, uniform particle size. By combining high capacity, high efficiency and low energy consumption, the Uni-Mill is ideal for pharmaceutical, food, chemical industries.

Uni-Millär designed and manufactured by Hanningfield Process Systems in England.

The Uni-Mill cone mill balances performance with simplicity, to provide a solution that guarantees a high capacity, it should be easy to use, clean and maintain. This durable construction makes the Uni-Mill extremely reliable, perfect even for the most demanding treatment requirements.

Uni-Mill is suitable for dry, wet or fine grinding in the pharmaceutical, food and chemical industries. The grinder can be easily adapted for processing different products, by changing the inserts (tools) and thus achieving a cost-effective solution to your grinding problem.

Uni-Mill is available in different sizes to ensure that all equipment is adapted to the customer’s specific requirements.

More information

Features:

- Hygienic stainless steel

- No metal-to-metal contact

- Gentle size reduction to particle size as low as 180μm (80 mesh)

- High energy efficiency

- Hygienic design

- Compact, space-saving design

- Mobile and height-adjustable versions

- ATEX Versions available

Advantages:

- High capacity

- Low proportion of “fines”

- Low heat development

- Low noise level

- Process flexibility with rapid tool changes

- Repeatable results, even particle size distribution

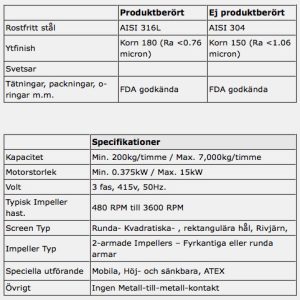

Technical specifications:

Typical applications:

The pharmaceutical industry

- Dry grinding for tablet production

- Wet milling for tablet manufacturing

- Agglomeration (hygiene screening) of raw materials

- Recycling/destruction of tablets or powder from capsules

The food industry

- Agglomeration of Raisin

- Recycling of cookies/biscuits (even with high fat content)

- Milk powder Porridge powder Spices

Cosmetic/Chemical industry

- Particle reduction of Salt

- Agglomeration of pigment

- Detergent (powder)

- Detergent (powder)

- Easy cleaning

- Mobil

Can be supplemented with a vacuum system (Uni-Vac) which supplies the machine with product and thus dust-free powder handling.